EUROPEAN AUTO TECH HEADLIGHT RESTORATION SERVICE

EUROPEAN AUTO TECH HEADLIGHT RESTORATION SERVICE

All new headlamps are made from durable polycarbonate plastic. They are nearly unbreakable, but have one draw back. They have to have a UV coating to keep them from discoloring. Here in the harsh Arizona sun, this can start degrading in as little as 3 to 4 years

New plastic headlight lenses have a factory applied UV coating to protect the plastic from degradation. Over time, harsh UV rays and road debris penetrate the factory UV coating resulting in hazing and yellowing. This hazing is not only unsightly, it is a serious safety concern, in fact hazed lenses reduce down-road illumination by 65% and increases oncoming driver glare by scattering light upward.

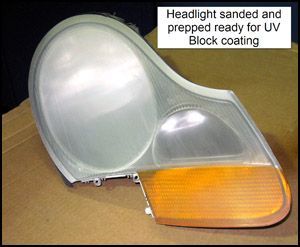

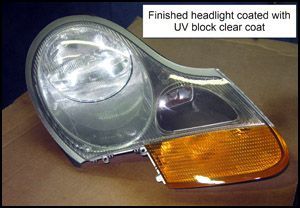

Unlike polishing or other lens restoration products designed just to remove the haze and yellowing, we here at European Auto tech restore the lens to like-new clarity and protection using a Professional Quality UV Block Clear Coat that has to be sprayed on using a professional spray gun.

First we sand off the damaged coating, making sure to remove all of the old UV coating, than apply a UV block clear coat to the lens.

The end result is a crystal clear headlight with a UV block coating that will last a very long time.

The first set we ever repaired is still clear and bright after 4 years in the Tucson sun

We are able to repair any car’s plastic headlights, contact us for pricing or an appointment